All these are employed for ultimately achieving a chopped AC signal whose duty cycle could be adjusted using a complex microcontroller circuit, finally providing the required. However we can experiment and try to accomplish a 3-phase induction motor speed control through a much simpler concept using the advanced zero crossing detector opto coupler ICs, a power triac and a PWM circuit. Using Zero Crossing Detector Opto Coupler Thanks to the MOC series of optocouplers which has made triac control circuits extremely safe and easy to configure, and allow a hassle free PWM integration for the intended controls. In one of my earlier posts I discussed a simple which implemented the MOC3063 IC for providing an effective soft start on the connected motor. Here too we use an identical method for enforcing the proposed 3 phase induction motor speed controller circuit, the following image shows how this can be done: In the figure we can see three identical MOC opto coupler stages configured in their standard triac regulator mode, and the input side integrated with a. The 3 MOC circuits are configured for handling the 3 phase AC input and delivering the same to the attached induction motor. The PWM input at the isolated LED control side of the opto determines the chopping ratio of the 3 phase AC input which is being processed by the MOC ICS.

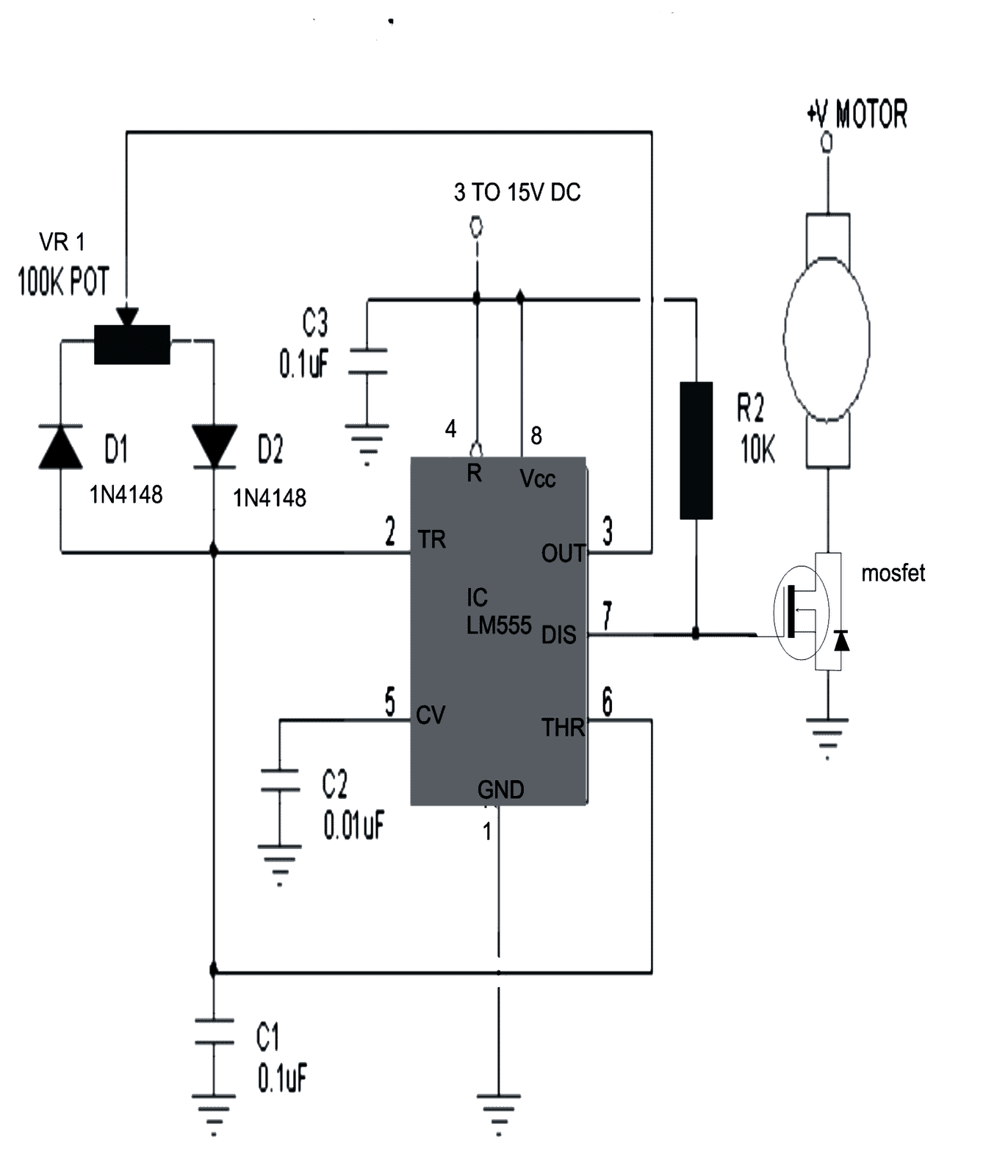

Using IC 555 PWM Controller That implies, by adjusting the PWM pot associated with the 555 IC one can effectively control the speed of the induction motor. Output at its pin#3 comes with a varying duty cycle which in turn switches the output triacs accordingly, resulting in either increasing the AC RMS value or decreasing the same. Increasing the RMS through wider PWMs enables acquiring a higher speed on the motor, while decreasing the AC RMS through narrower PWMs produces an opposite effect, that is it causes the motor to proportionately slow down. The above features are implemented with a lot of precision and safety since the ICs are assigned with many internal sophisticated features, specifically intended for driving triacs and heavy inductive loads such as inductions motors, solenoids, valves, contactors, solid state relays etc.

The IC also ensures a perfectly isolated operation for the DC stage which allows the user to make the adjustments without the fear of an electric shock. The principle can be also efficiently used for controlling single phase motor speed, by employing a single MOC IC instead of 3. The design is actually based on theory. The existing upper IC555 PWM circuit may be adjusted to produce a 50% duty cycle at much higher frequency while the lower new PWM circuit may be used for controlling the speed of the induction through the associated pot. This 555 IC is recommended to have relatively lower frequency than the upper IC 555 circuit. This may be done by increasing the pin#6/2 capacitor to around 100nF. Assumed Waveform and Phase Control using the above Concept: The above explained method of controlling a 3-phase induction motor is actually quite crude since it has no V/Hz control.

It simply employs switching the mains ON/OFF at different rates to produce an average power to the motor and control the speed by altering this average AC to the motor. A more technical approach is to design a circuit which ensures a proper control of the V/Hz ratio and automatically adjusts the same depending on the speed of the slip or any voltage fluctuations. Circuit Database. (15). (45). (32). (95).

(59). (14).

(5). (100). (6).

(6). (20). (53). (26). (18). (12). (1).

(176). (30). (39).

(69). (87). (20). (7). (8). (36).

(13). (64). (23). (63). (2).

(1). (10).

(46). (27). (46).

(60). (8). (14). (98). (8).

(106). (21).

(11). (4). (8).

(38). (19). (55). (19). (34). (1).

(2). (8). (35). (24). (77).

(1). (29). (39).

(4). (2). (25). (72).

(8). (16). (15). (8). (54).

(1). (28). (20). (9). (14).

(108). (2). (19).

(10). (5). (1).

(16). (46). (3). Hi, I am trying to figure out how to modify the newer 3phase washing machine motor controllers on say a Maytag Neptune along with the existing motor of course.

Basically I would like to use the existing VFD on the machine by taping into the signals for speed and direction. These motors are perfect for many jobs and are now available in the junk yard for cheap $.

The motors tend to be 120v 3phase and 120v RFDs are very hard to find. All seem to be 220v out.

Ac Motor Control Schematic

Any thoughts or should I just start reading the computer outputs during the various speeds and direction. It seems to me we have a very capable and cheap motor system being thrown out daily that we could all be using with a little smart sleuthing. My first use would be a chimney top fan unit to improve the output of my home build gasification wood boiler. I have a Neptune at the ready for parts. These are induction and not permanent magnet like the direct drive machines we read about.

Thank you Richards, however please ignore my recent modifications for the first circuit, it might not work correctly, because the PWM is supposed to be released in bursts, therefore two IC 555s will be required, sometimes too much analysis results in mistaken assumptions. The idea is simple, we break or interrupt the 50Hz mains supply to the motor and prevent the motor from getting a continuous mains supply, in this way the motor is able to get a reduced average power from the mains, causing a proportionate drop in its avearge speed level accordingly.

Hi Richards, for the first design 4049 will not be required. There’s one modification I just now realized which can be tried in the first design.

Ac Motor Circuit

Connect the Rin common side with the 5V supply, and remove the upper IC 555 stage entirely. Now use only the lower IC 555 circuit and configure its output pin#3 to the pin#1 of the MOC ICs through separate 1N4148 diodesthe anodes of the individual diodeswill go to pin#1 of the MOC. Please try this this looks to be a much better idea for achieving the speed control. Dear Swagatam Ji, Namskar! I have to run a hoist. Hoist motor details- 220 volt ac single phase 60 hz 900 watt Motor winding resistance – 8.7 ohm Load capacity -500 kg / 250 kg lifting speed – 10 m / 5 m per minute My requirements – Lifting load – 150 kg Speed – 8 m to 4 m per minute.

Here in India power supply is 220- 240 volt at 50 hz. Please suggest me.

Can I use above mentioned hoist at 50 hz power supply. My load and speed is well within limit. Does hoist need any additional attachment like small fan for extra cooling, hz converter etc. What changes will occur in initial current (surge current) and running current when 220 v 60 hz motor used at 240 v 50 hz. After successful testing I will run hoist on a inverter. I want to use 6 no.

Fan dimmer in parallel to handle above mentioned hoist initially surge current. To avoid higher capacity inverter requirement. Will this work. Thank you very much.

Swagatam I have finaly the components received from aliexpress and completed the build of this circuit. With the last info about the 100NF capacitor the speed control works but not as i expected. It works with some hick-ups and not at a continuous speed. The soft start works also but my question is the following, is it possible to increase the delay time for the soft start so it takes some more time to go to full speed. I hope you can help me out there because it is still a little to fast for me.

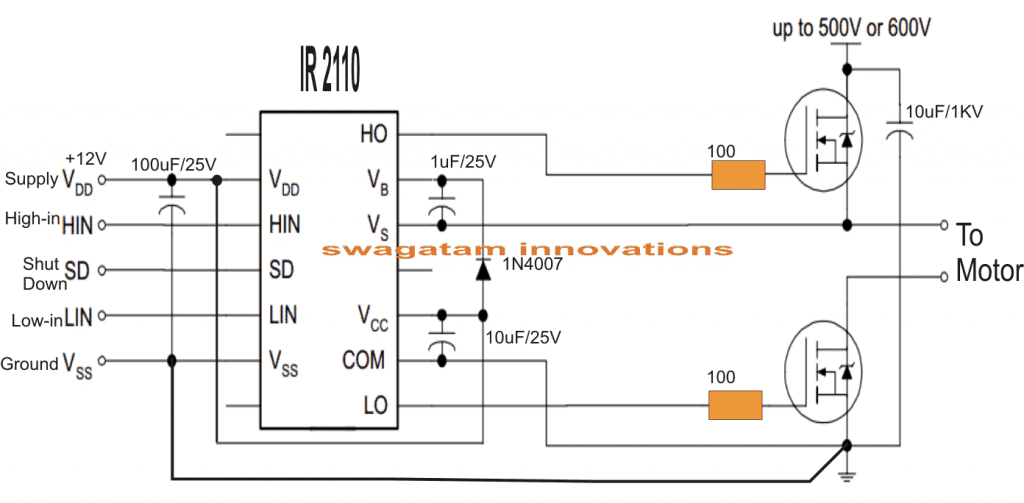

Hi Swagatham, Can you tell me how we can provide deadtime and shoot-through protection for the MOSFETS? Is there a logic circuit which will address these issues, so that the output from this circuit will go to the ITRIP of the driver. I am using IR2136 as the gate driver since IRS2330 is not available at my location. And IR2136 provides Under Voltage protection and as you mentioned the 1 ohm 40 watt with 1k preset protects the system against overload and overcurrent situations.

However, I experienced the damage of 6 MOSFET pack twice, (the gate and sources of the MOSFETs are getting shorted). After investigating I am suspecting that this was due to dead times and shoot through. Can you share your thoughts on this? Hi Uday, the dead time is internally fixed for this IC, here's what its datasheet says: 'This family of HVICs features integrated deadtime protection circuitry. The deadtime for these ICs is fixed; other ICs within IR’s HVIC portfolio feature programmable deadtime for greater design flexibility. The deadtime feature inserts a time period (a minimum deadtime) in which both the high- and low-side power switches are held off; this is done to ensure that the power switch being turned off has fully turned off before the second power switch is turned on.

This minimum deadtime is automatically inserted whenever the external deadtime is shorter than DT; external deadtimes larger than DT are not modified by the gate driver. Figure 5 illustrates the deadtime period and the relationship between the output gate signals. The deadtime circuitry of the IRS233(0,2)(D) is matched with respect to the high- and low-side outputs of a given channel; additionally, the deadtimes of each of the three channels are matched' still you can try adding 12V zener diodes in series with all the outputs of the NOT gates and see if it helps to increase the same externally. Hi Uday, you cannot check a mosfet with a meter, it can be a somewhat complex process to test a mosfet with a meter. The easiest method is to connect the mosfet as a switch and check its response as shown here deadtime is an IC is introduced to make sure that the mosfets across the two channels can never be ON during the brief transition periods, that is during the instantaneous periods when the IC may be switching from one of its output to the other. Deadtime creates a dead zone during these transition periods and this allows the meosfets to switch OFF completely during these periods, which in turn keeps the mosfets safe from burning.

Let me ask you one more request. I have built the circuit suggested by you and successfully drove an induction motor.

However I need to operate it at its maximum torque value. If you could remember torque speed characteristics I need to stay at top of the curve. Can you suggest me how to get there.

In general I can do with VFD circuit which you mentioned in other thread. But the complication here is I need to automate the maximum torque operation, which means the motor torque should adjust itself and stay at max torque with the load changes. Thanks in advance Uday. Sir The old post triac based motor speed control, if we avoid the pwm control section and power circuit use for just on and off for a low voltage three phase induction motor (100 volt to 150 volt) frequently with help of a on off sensor,in 100 or more voltage,motor too hot after some time running.if apply 50v three phase it will be working fine.but in 50 volt it does not work with full speed.can you give any suggestion. And can you post a relay tripping circuit if the motor over heated or mechanically jam. Thanks Ajitkumar. Ajitkumar, the zero crossing will not have much impact if the frequency of the upper 555 IC is set to a reasonably high level.

Because if the frequency is high one of the pulse will be able to somehow catch hold of the zero crossing start point and trigger the triac, The zero crossing basically helps to reduce RF interference to the minimum. Having said this it would also interesting to see how a non-zero-crossing opto coupler responds with this circuit I'll try to update the mosfet version soon next weekif i forget please do remind me.

Electroschematics.com AC Motor Speed Controller Circuit 400 × 246 - 21k - gif aaroncake.net AC Motor Speed Controller 603 × 263 - 5k - gif electronics-diy.com AC Motor Speed Controller 540 × 300 - 10k - png eewiki.net Stepping Motor Control (with VHDL) - Logic - eewiki 1316 × 529 - 78k - jpg electroschematics.com AC Motor Speed Controller Circuit 660 × 340 - 5k - gif electroschematics.com AC Motor Speed Controller Circuit 500 × 204 - 22k - gif electronicdesign.com Capacitive Isolated Gate Drivers Spin AC Induction Motors. 800 × 231 - 39k - jpg instructables.com How do I control this motor? 750 × 500 - 45k - jpg twovolt.com AC Motor Speed Controller Using U2008 Current Feedback - Circuit. 727 × 505 - 35k - jpg next.gr motor control circuit Page 10: Automation Circuits:: Next.gr 800 × 334 - 18k - gif pinterest.com induction motor controller circuits - Yahoo Image Search results. 881 × 387 - 8k - png acdrive.org AC Drive Working Principle 429 × 207 - 15k - jpg farhek.com Induction Motor Power Controller Project Kit Block Diagram.

2476 × 1726 - 340k - jpg homemade-circuits.com Single Phase Variable Frequency Drive VFD Circuit 1392 × 684 - 172k - png brighthubengineering.com How to Build a High Torque DC Motor Speed Controller Circuit 600 × 600 - 27k - jpg technoshamanarchist.net AC Motor Speed Controller and NEMA 34 Motors Technoshaman's. 807 × 571 - 61k - jpg logosfoundation.org 2113 - Motor Speed Control for 3-phase induction motors - dr. 894 × 1211 - 29k - gif homemade-circuits.com Simple DC Motor Speed Controller Circuit 1372 × 1600 - 213k - png nxp.com 3-Phase AC Induction Motor Reference Design NXP 695 × 489 - 43k - gif electronics-diy.com H-Bridge DC- Motor Motion Controller 800 × 672 - 48k - gif.